The Challenge

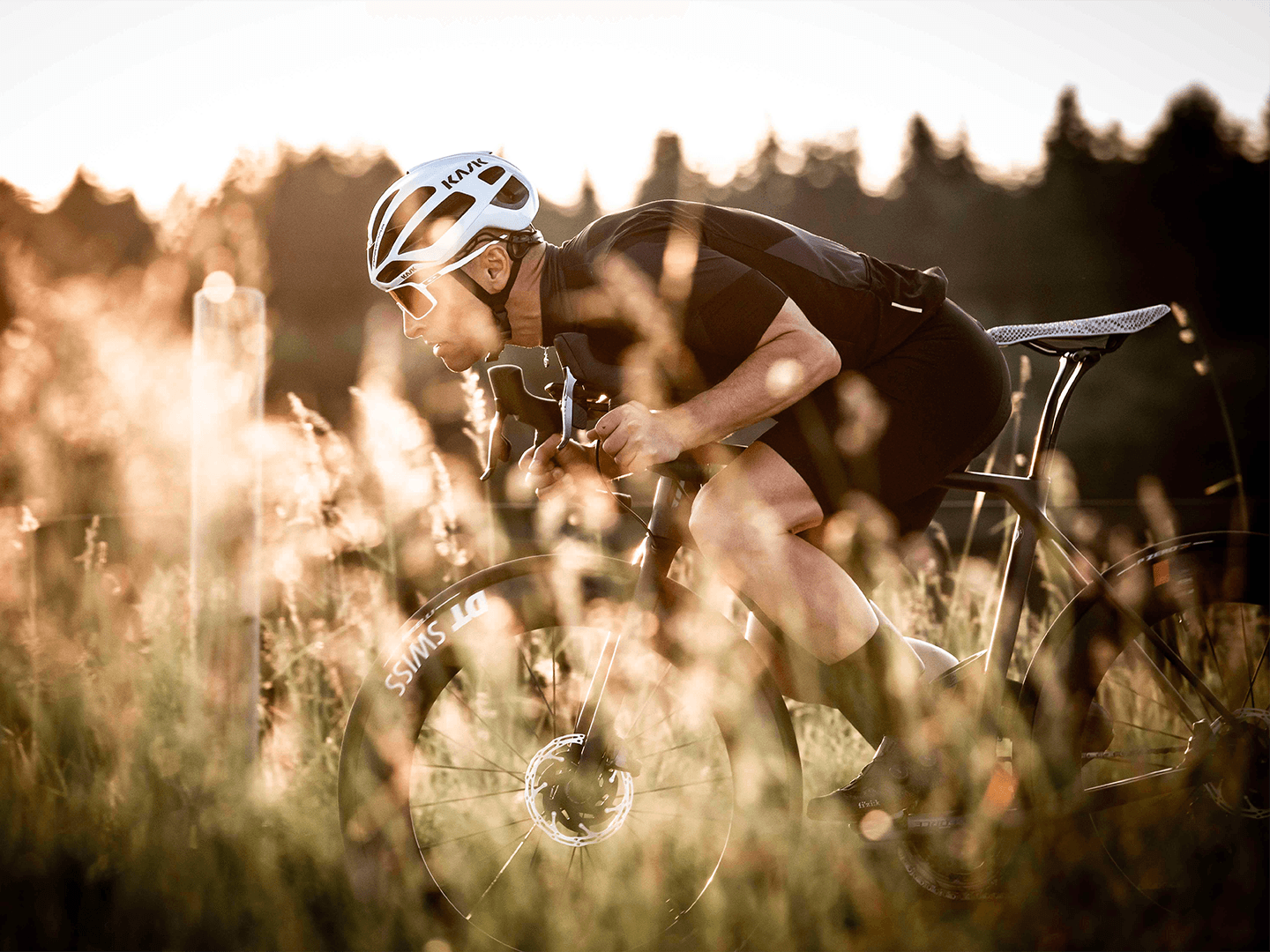

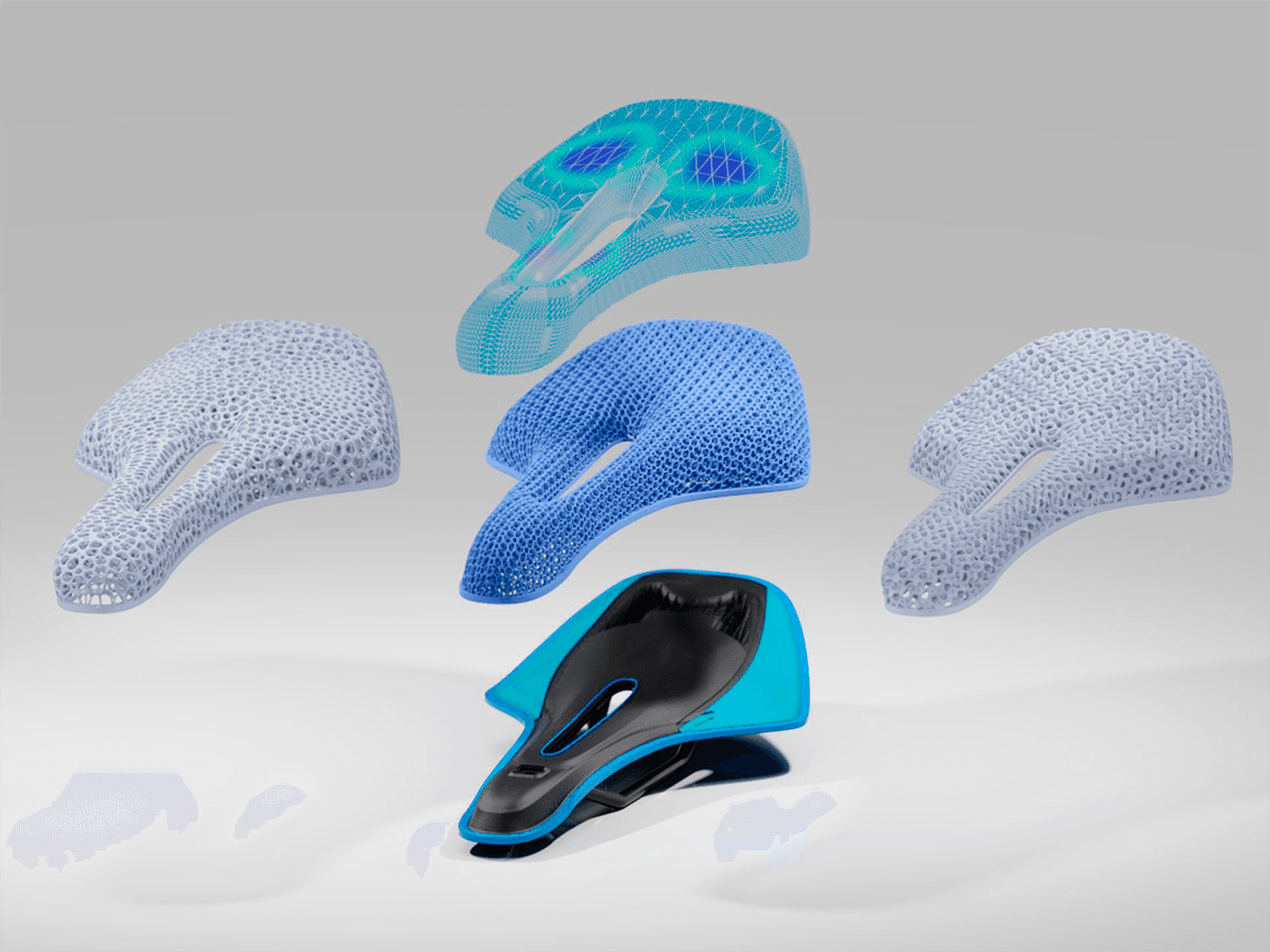

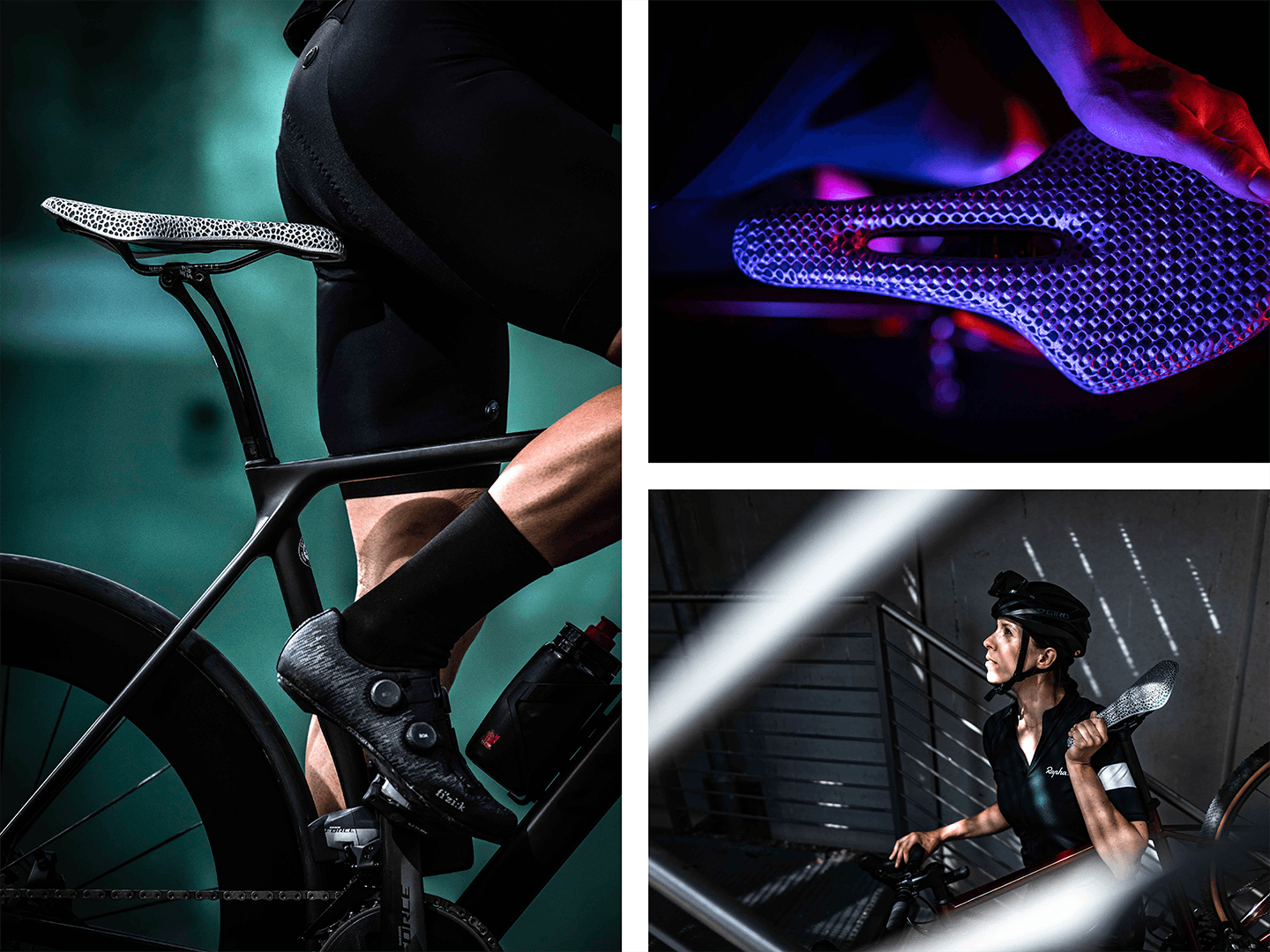

Hyperganic, together with Fizik, BASF Forward AM, atum3D, and Innovation Lab, aimed to transform the cycling experience by addressing the limitations of off-the-shelf bicycle saddles. The objective was to provide both casual and competitive cyclists with saddles tailored to their individual physiques, bridging the gap between standard foam saddles and the need for personalized performance enhancements.

The Results

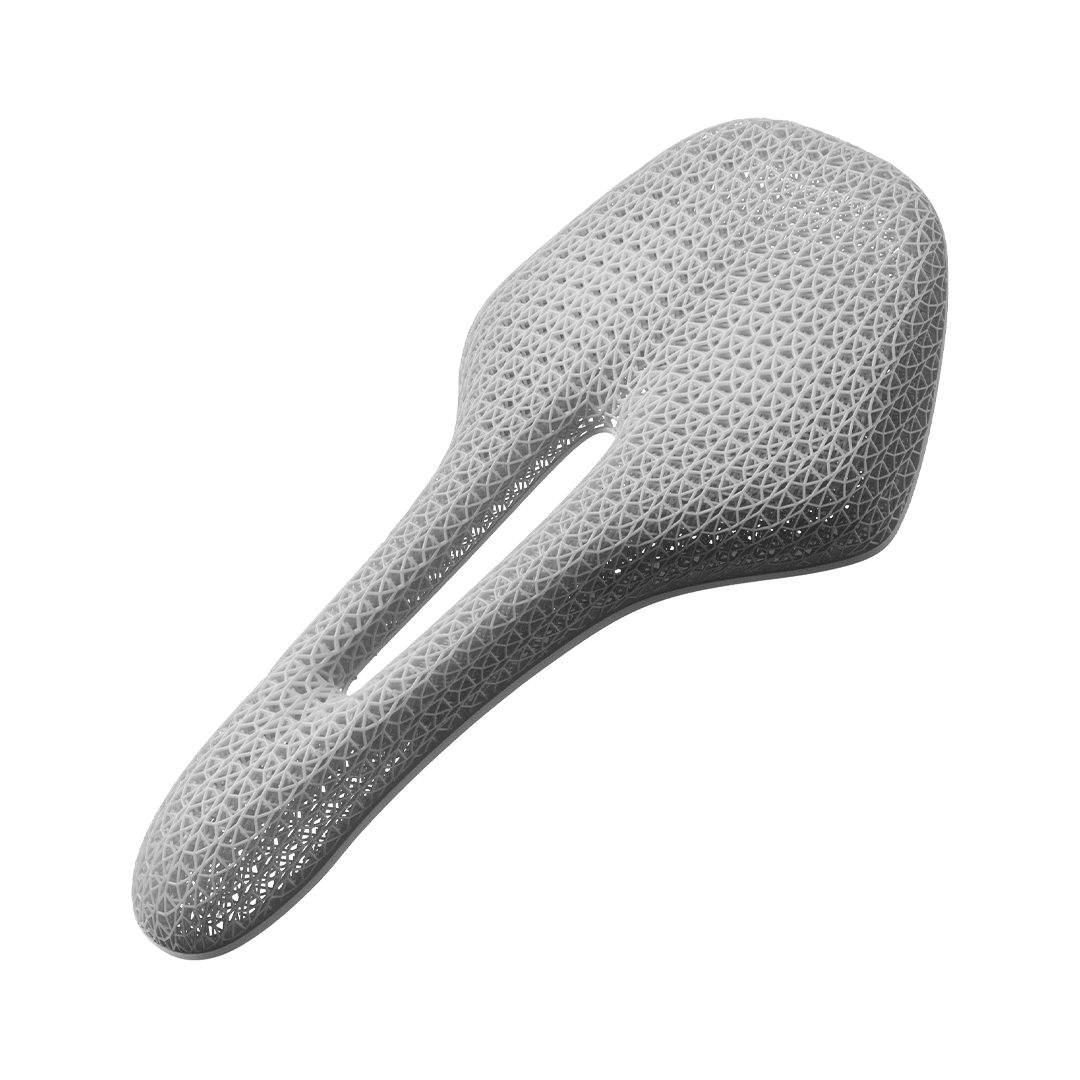

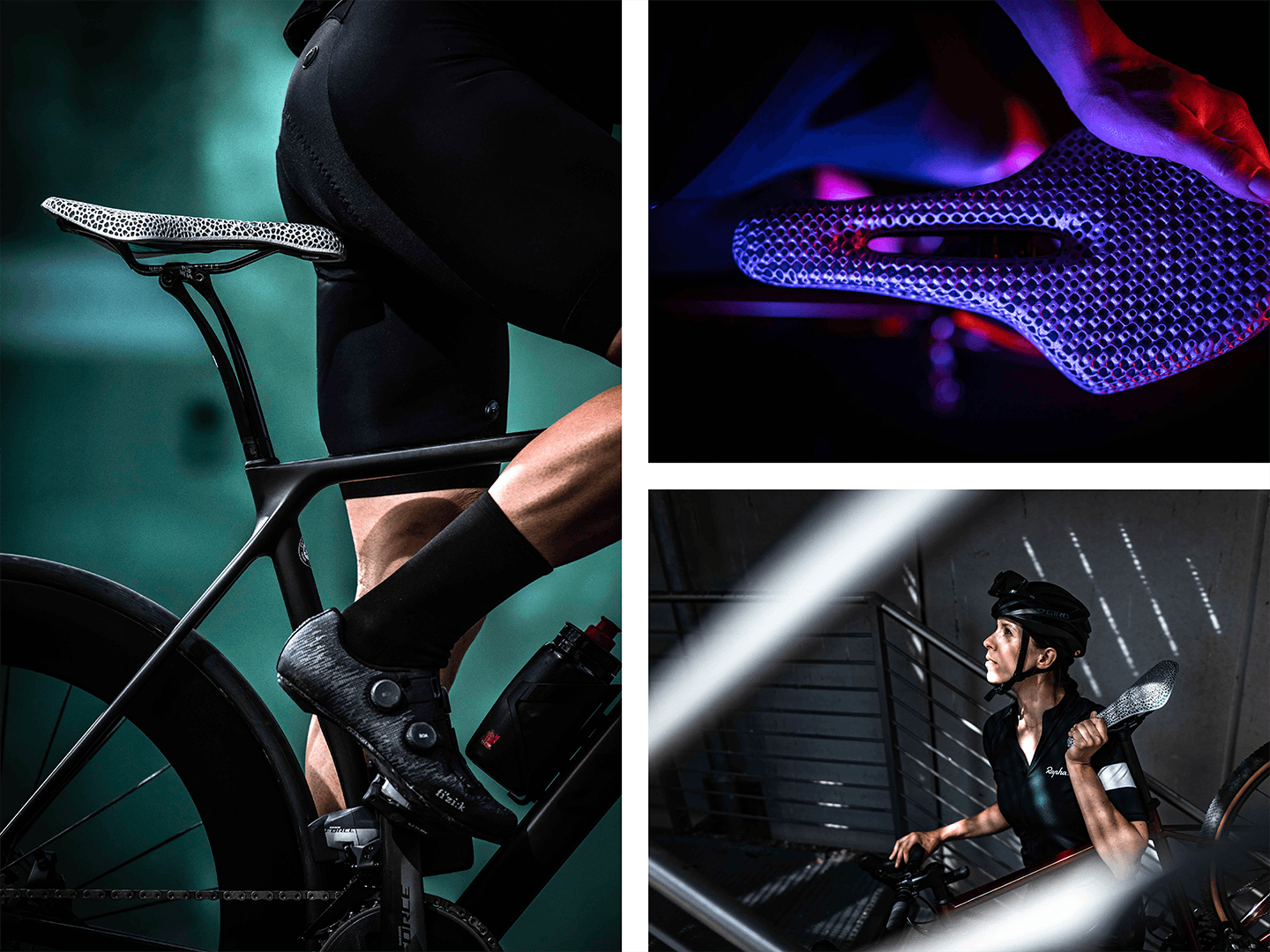

This collaboration yielded saddles that perfectly balance stiffness and compliance, thanks to the innovative use of BASF Forward AM's Ultracur3D® EL 150 material and atum3D’s DLP Station 5-365 EXZ printer. The project not only showcased the potential of 3D printing and algorithmic engineering in producing bespoke cycling saddles at scale but also set a new standard for the consumer goods industry. By embracing mass customization, Hyperganic and its partners have paved the way for a future where consumer products are uniquely tailored to each individual, enhancing performance and comfort for all cyclists.

“3D Printing technology has been the dawn of a new era for performance cycling saddles, it gave us the ability to design paddings with seamlessly engineered zonal cushioning without the constraints or limitations imposed by traditional production methods and materials. But we are yet to tap into the true potential of this manufacturing technology, the ability to serially produce individual bespoke solutions for every cyclist.

Starting from riders’ biometric information, Algorithmic Engineering proves to be a key step towards mass customization, and we have made it a reality with Hyperganic.”

Giovanni Fogal Brand Manager, Fizik

This case study illustrates a significant leap towards the personalization of sporting equipment, demonstrating how cutting-edge technology can meet the specific needs of consumers in a sustainable and efficient manner.