The Challenge

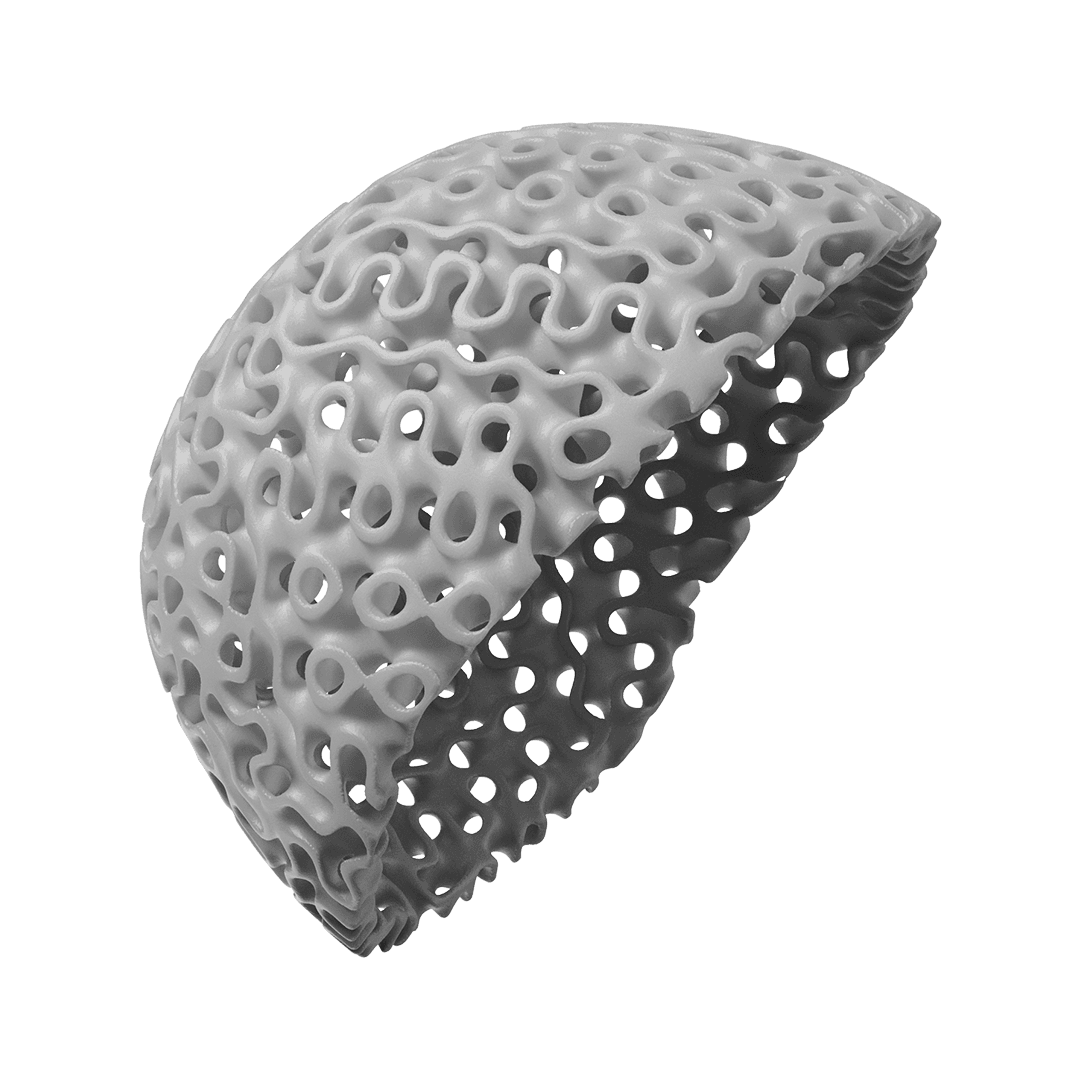

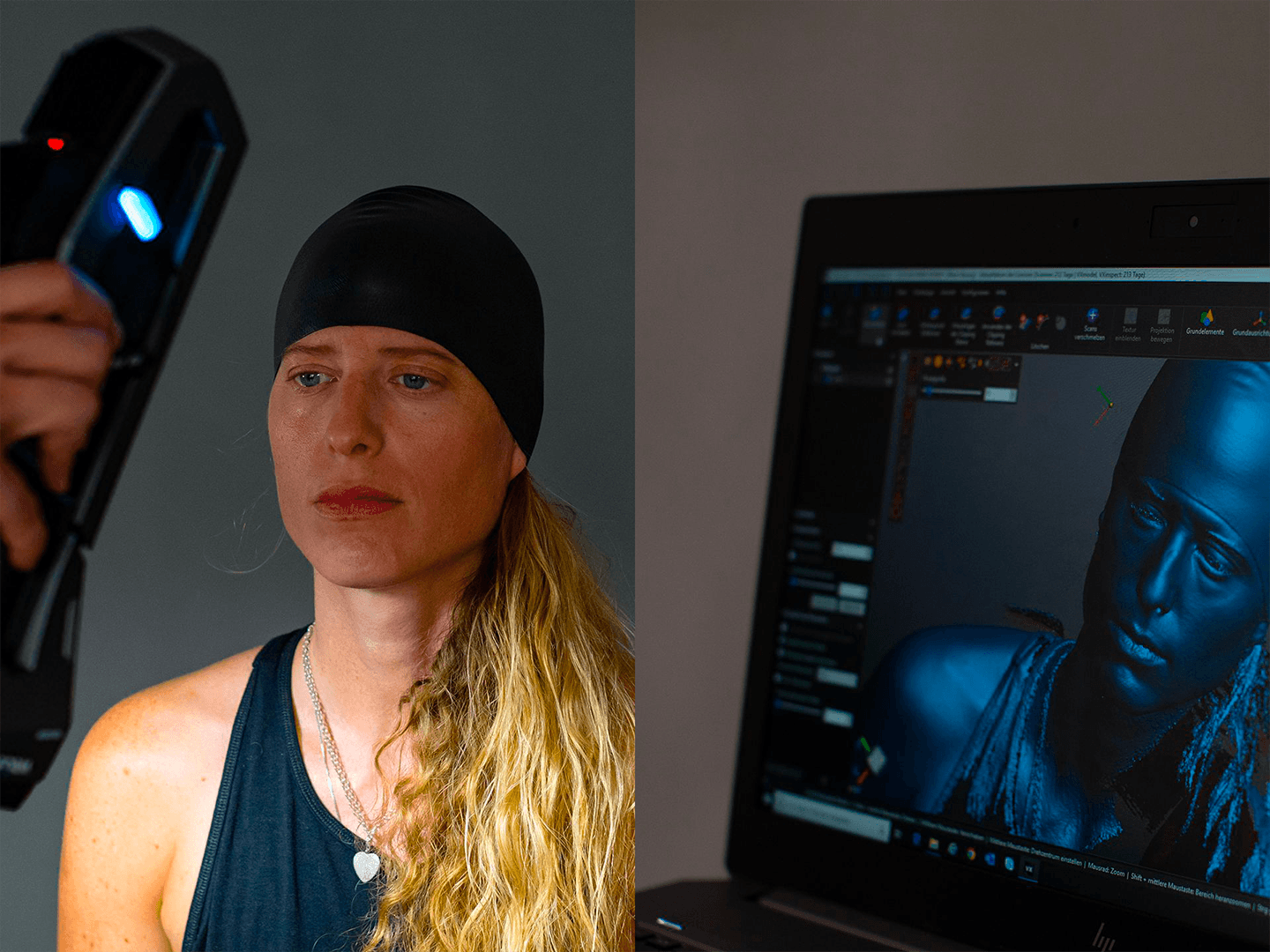

The project aimed to revolutionize bicycle helmet safety and comfort by shifting from mass production to individualized manufacturing. Traditional helmet design tools and methods limited creative freedom, making it challenging to engineer helmets that fit the diverse shapes of human heads while ensuring optimum performance. The team, alongside Hyperganic Core, faced the task of creating a scalable, automated process to design helmets that provide a personalized fit, superior aerodynamics, and enhanced safety for every cyclist.