The Challenge

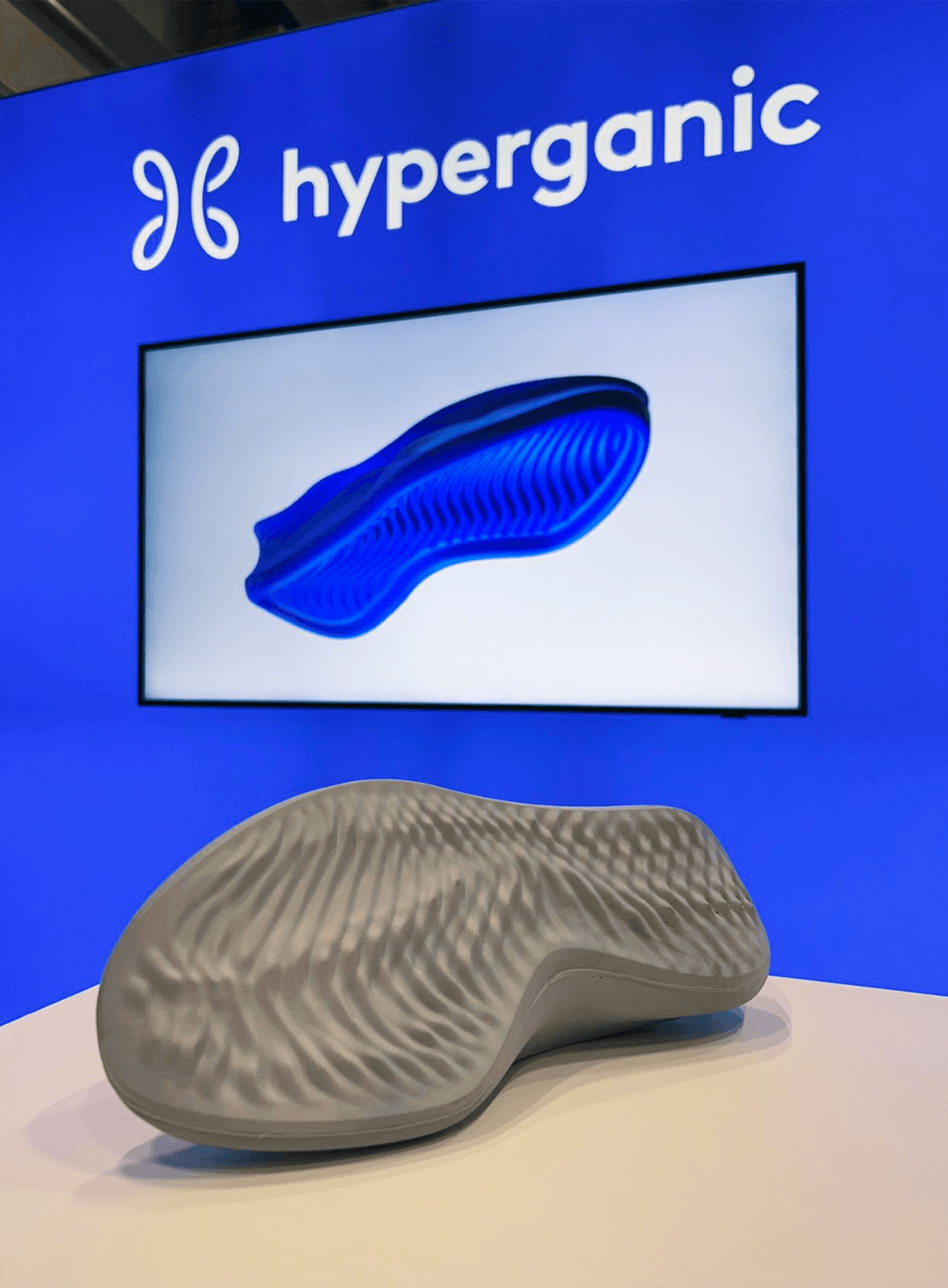

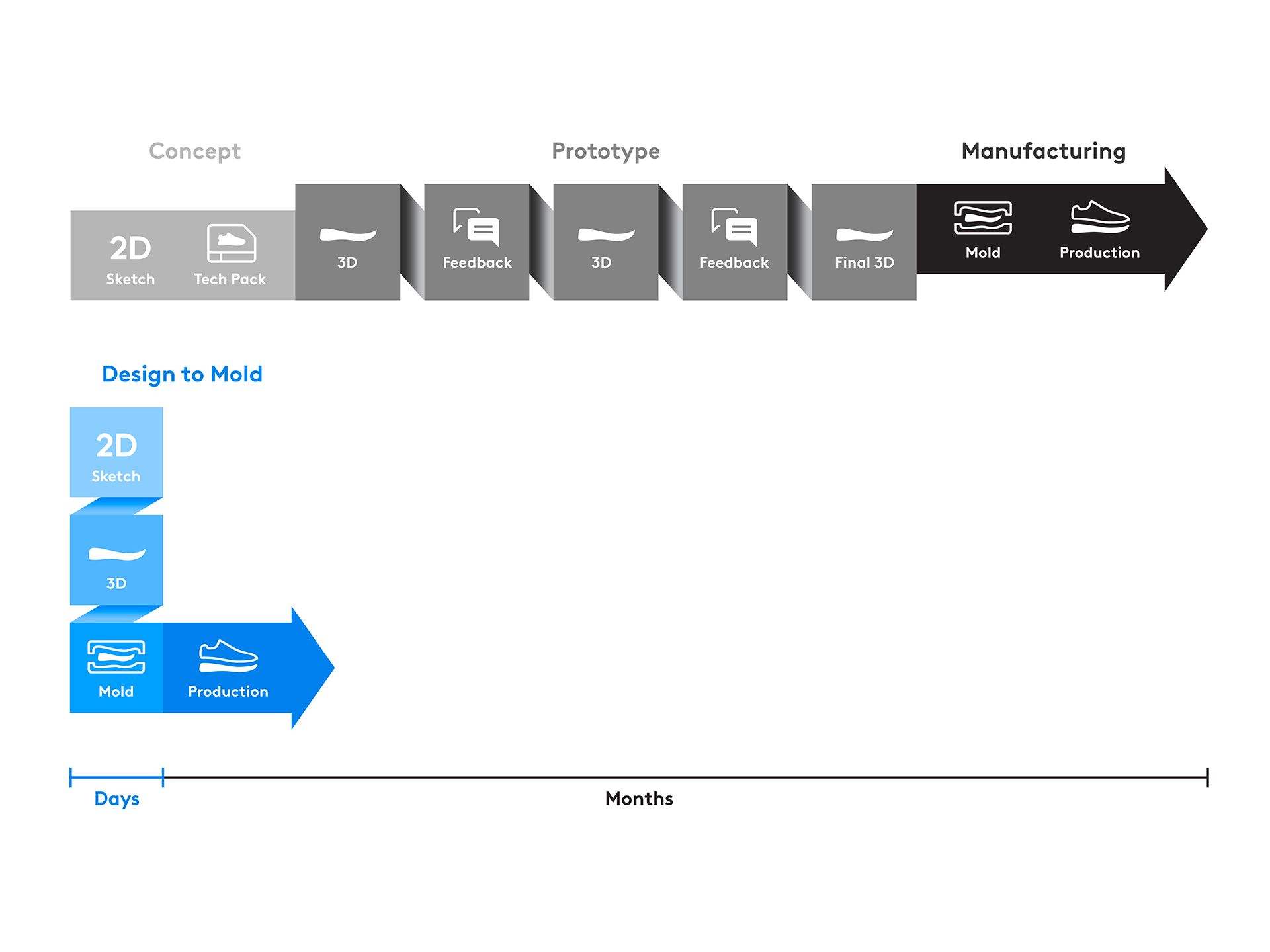

In the traditionally slow-moving footwear industry, Hyperganic, in collaboration with DESMA and footwear designer Daniel Shirley, aimed to shatter the lengthy production cycle. The goal was to transform shoe manufacturing from a cumbersome, year-long process fraught with inefficiencies and wasteful overproduction into a streamlined, responsive workflow capable of adapting quickly to market demands.

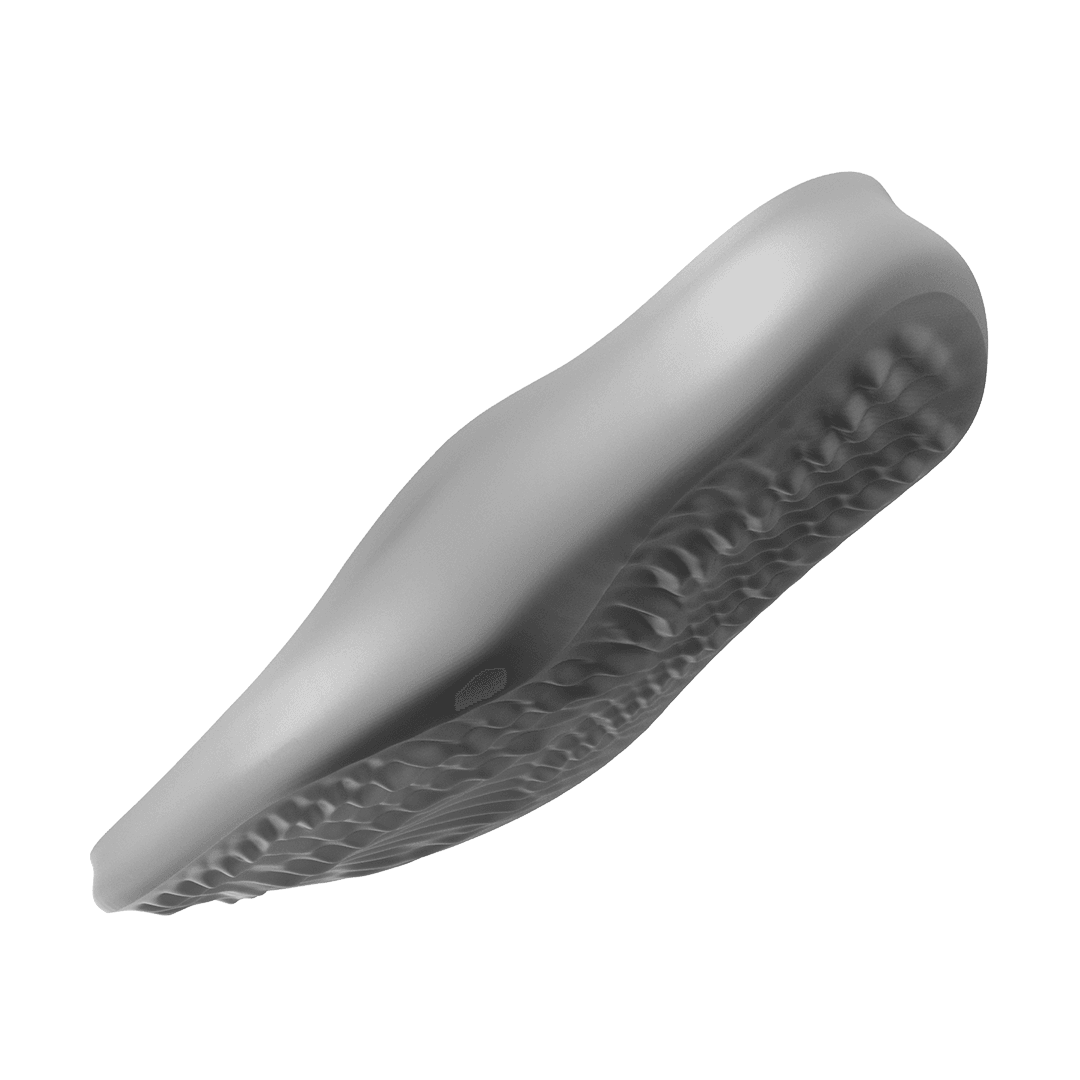

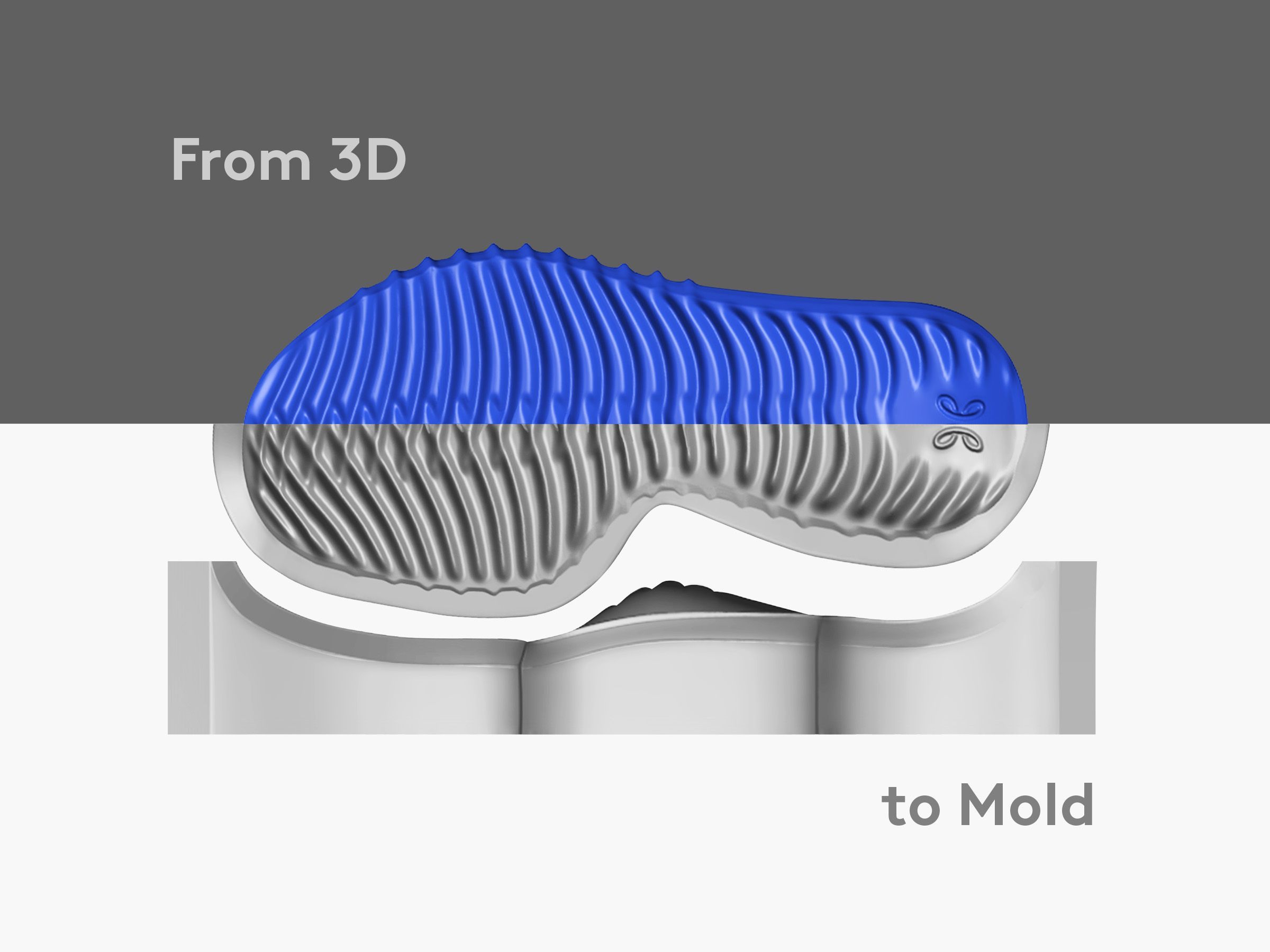

Traditional footwear production process is lengthy and prone to communication barriers in the 3D modelling stage